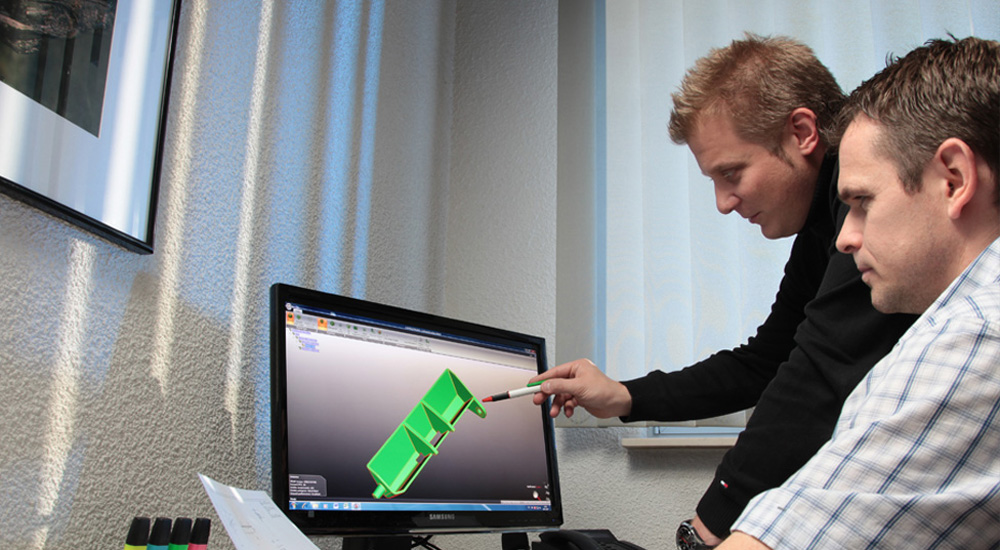

CAD design

Prototypes

Development / design

We accompany and support you - from your initial idea via the develop-ment stage through to the finished series product. Thanks to our many years of experience in the manufacturing of composite metal-plastic sub-assemblies, we are able to full in particular the stringent requirements of the automotive and commercial vehicle sectors as well as those set in transport securing systems, the packaging industry, the area of fish-keeping and aquariums and in the medical and dental technology. In today‘s ever-shorter „Time to Market“ development times, we ac-celerate the development processes with the aid of the most modern 3D-CAD systems, fast and flexible „rapid prototyping“ and mould-flow analyses.

In accordance with your requirements and our know-how, your project will pass through our production process development stages so that your product can go into series production with an optimum costperformance ratio in the very shortest time.

We accompany and support you - from your initial idea via the develop-ment stage through to the finished series product. Thanks to our many years of experience in the manufacturing of composite metal-plastic sub-assemblies, we are able to full in particular the stringent requirements of the automotive and commercial vehicle sectors as well as those set in transport securing systems, the packaging industry, the area of fish-keeping and aquariums and in the medical and dental technology. In today‘s ever-shorter „Time to Market“ development times, we ac-celerate the development processes with the aid of the most modern 3D-CAD systems, fast and flexible „rapid prototyping“ and mould-flow analyses.

In accordance with your requirements and our know-how, your project will pass through our production process development stages so that your product can go into series production with an optimum costperformance ratio in the very shortest time.

Advising of customers

We support and accompany you from the initial statement of task through to series production. Depending on your requirements prototypes and tools/moulds will be produced on request in order to be able to move into series production with the optimum price-performance ratio.

Stockholding/ logistics

In a short time we will have in our new logistics and goods distribution centre with a floor area of more than 1,500 m2 the capacity to meet every customer requirement.

In addition we can fill special outer packaging units or packaging units made available by our customers at any time.

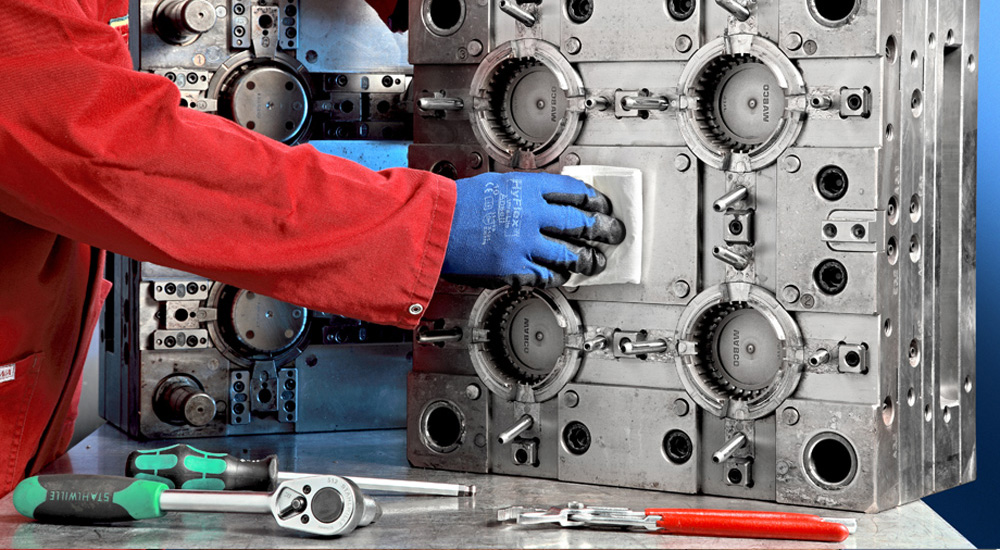

Mould maintenance

In order to be able to ensure that article quality remains high and uniform over extended periods, each mould is subjected to regular maintenance and servicing.

Storage/upkeep

To ensure the highest level of safety our complete building is monitored by a fire alarm system. Each injection moulding mould is stored in a specially fire-proofed room in a specifically assigned place.